3D PRINTING

How does 3D Printing compare to Injection Molding?

As 3D printing is solidifying its hold on the enterprise landscape, companies are spotting new opportunities and ideas that were not financially or economically viable before. 3D printing has earned its place next to Injection Molding because of the advantages it provides. 3D printing in combination with Injection Molding unlocks new possibilities for customer experience in terms of speed and customization options. Are you someone that gets requests from client to adjust some fine detail because it would fit his use case better? Then be sure to read on!

Not sure what 3D printing could offer you? We listed the advantages below!

3D PRINTING FOR YOU

Improve your Customer Experience in all Three Dimensions

Delivery speed and adaptability are some of the leading indicators of a good Customer Experience. Businesses often thrive on maximizing customer value. 3D printing proved to be game-changing in that process, as Nike has already demonstrated. When Nike started to 3D print shoes for indvidual customers it shifted its focus from selling athletic shoes to creating an ecosystem around customer’s individual health. Consequently, Nike is able to build a much stronger relationship between their brand and customer. Just like Nike, you too can offer custom and personalised products without facing the restrictions of Injection Molding.

3D Printing

Injection Moulding

Average Turnaround Weeks

Average Production Volume

Design Fexlibility during production

Very Large Parts

Average Start-up Cost (€)

Small Backorder Quantities

No Need to Choose

Some 3D printing techniques can be beneficial to use for Injection Molding. Stereolithography (SLA), Digital Light Processing (DLP) and Mask Stereolithography (MSLA) are printing technologies that use a UV-sensitive resin to produce objects. In contrast to Fused Filament Fabrication (FFF) or Fused Depostion Modeling (FDM), the above mentioned techniques create a much smoother finish on the object because of its high print resolution. In combination with a solid fill and isotropic characteristics, it becomes resistant to high pressure and thus becomes suitable for making low-volume Injection Molding moulds.

Want to know more? Don’t hesitate to contact us so we can talk about the 3D printing opportunities for your company.

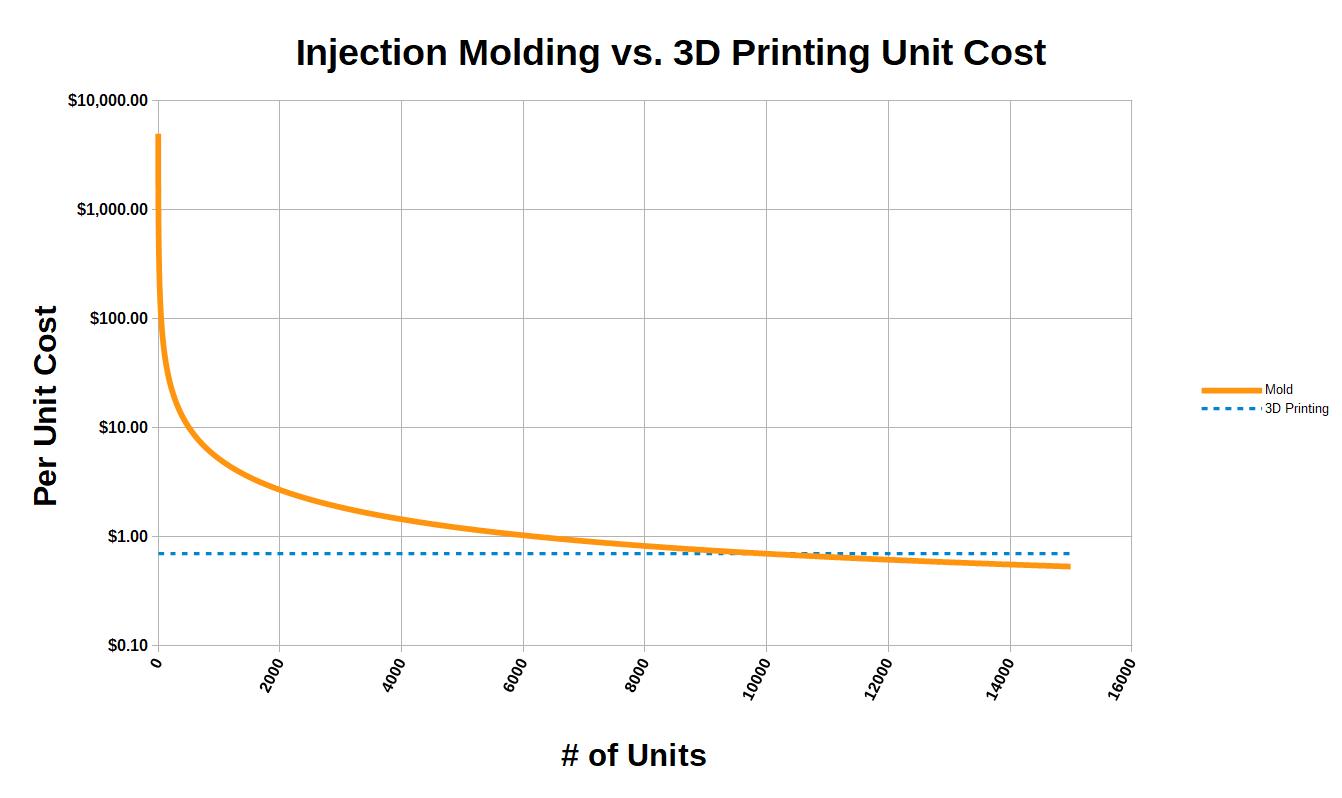

Cost-per-Unit

3D printing is usually the best option for smaller production batches. That’s because the unit cost of injection molding of smaller batches is a lot higher for the first couple of thousand units. When adding the cost benefit of 3D printing to it’s other advantages over injection molding, such as design flexbility, 3D printing makes a very compelling case for itself.