Optimize Workflows with 3D Printed Tools

In the fast-paced realm of scientific research and experimentation, innovation drives progress. However, amidst this dynamic environment, the significance of the tools utilized for experiments often goes unnoticed. Nonetheless, workflows can be optimized with 3D printed tools.

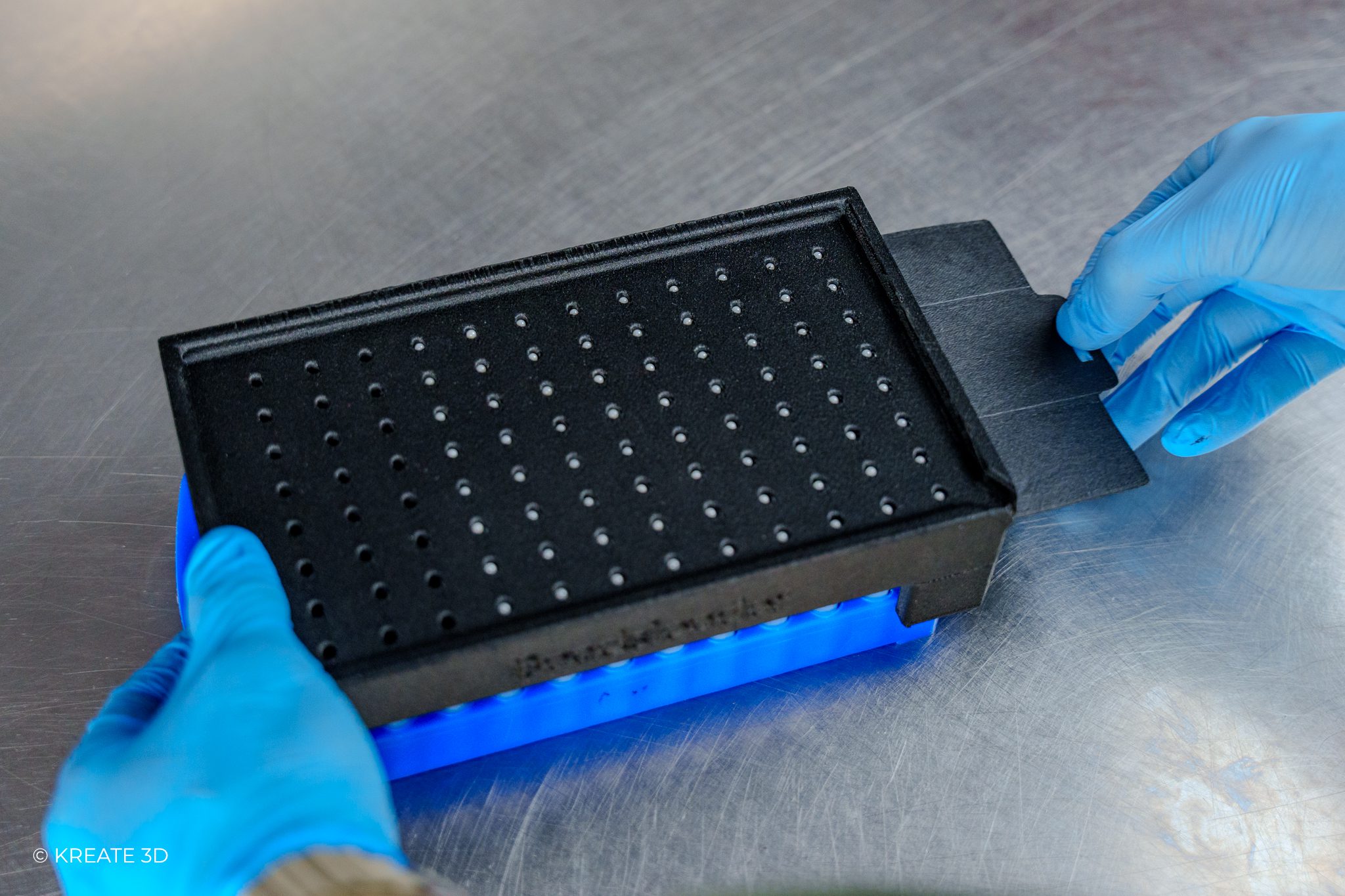

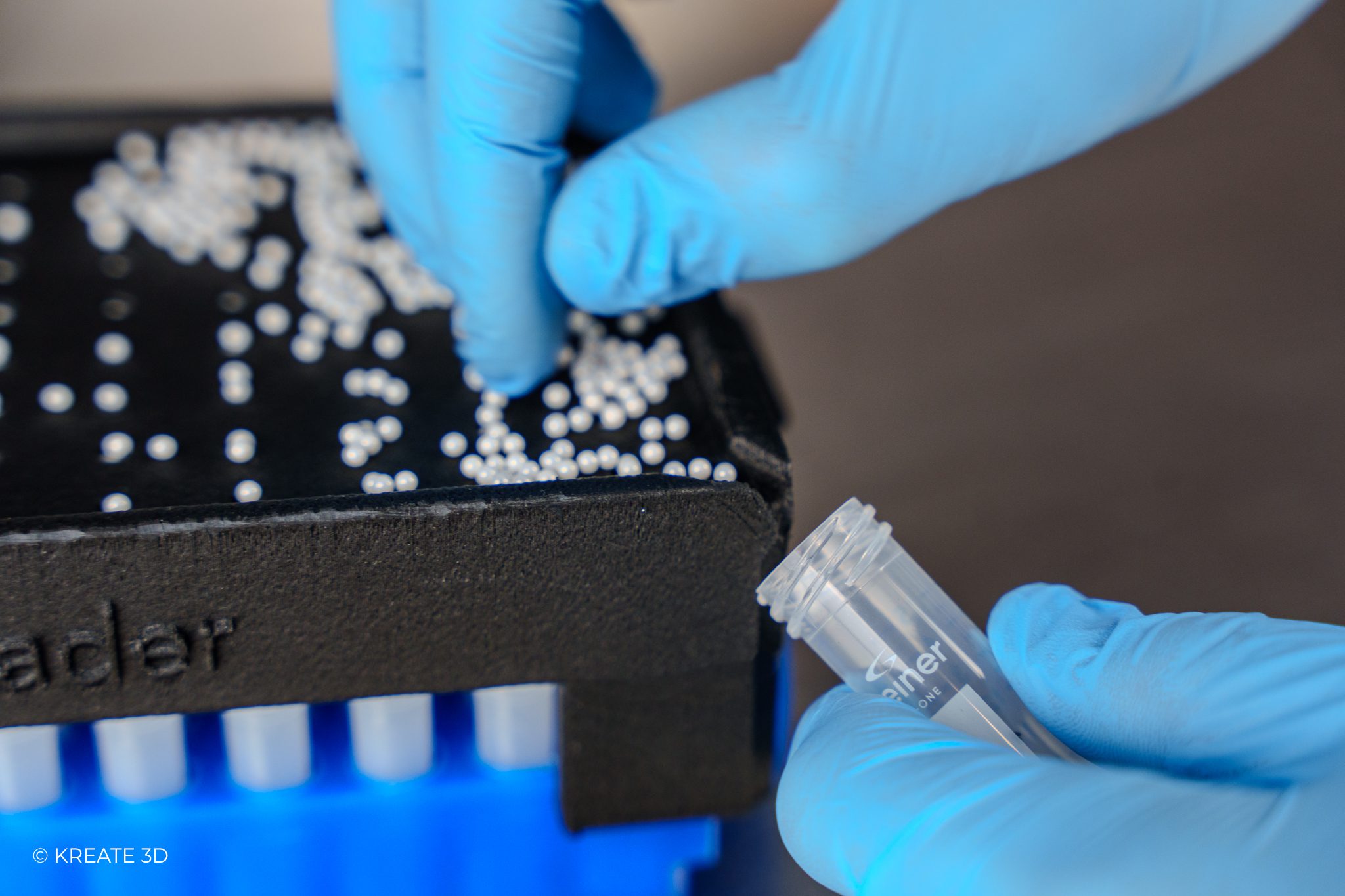

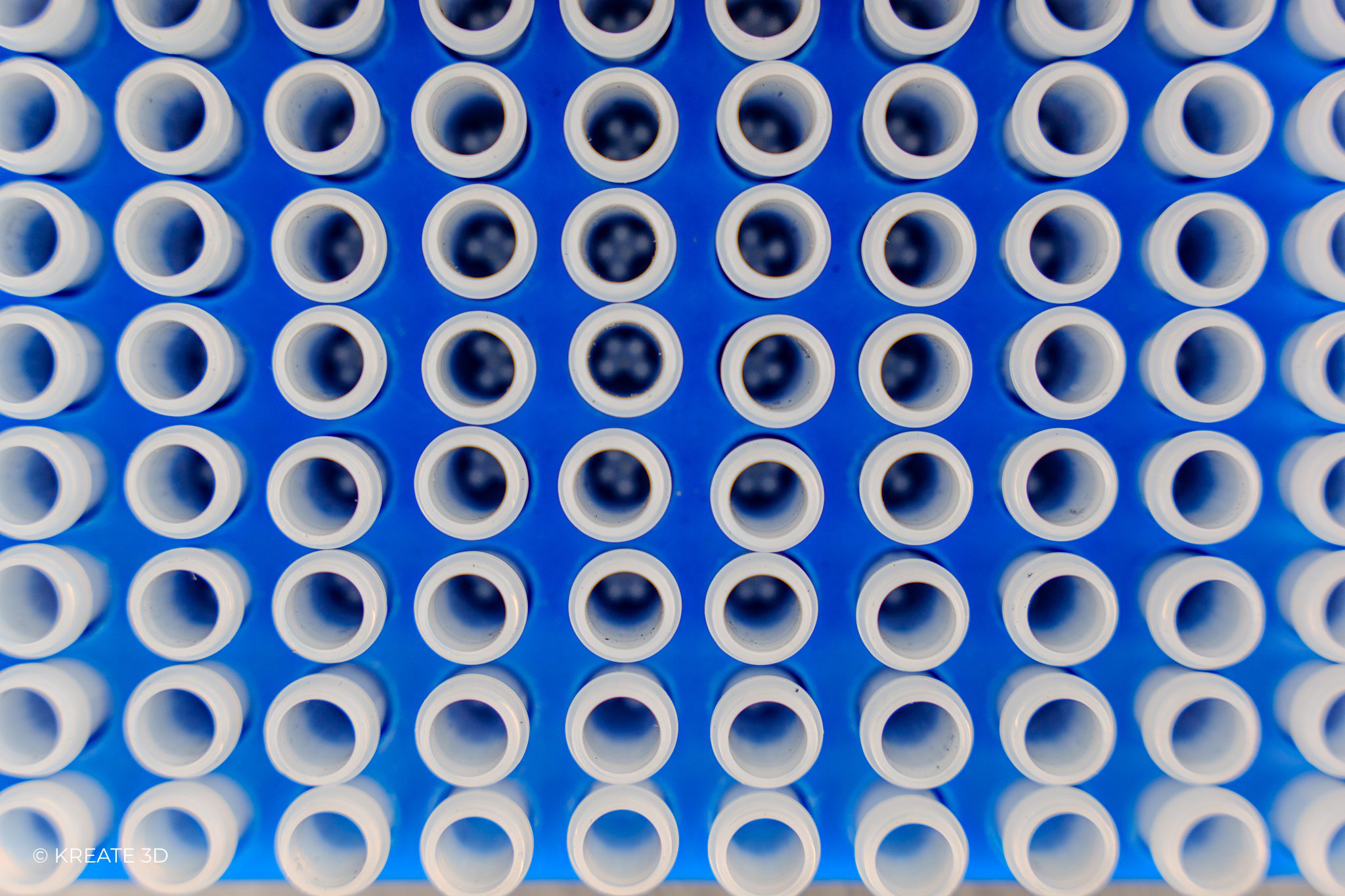

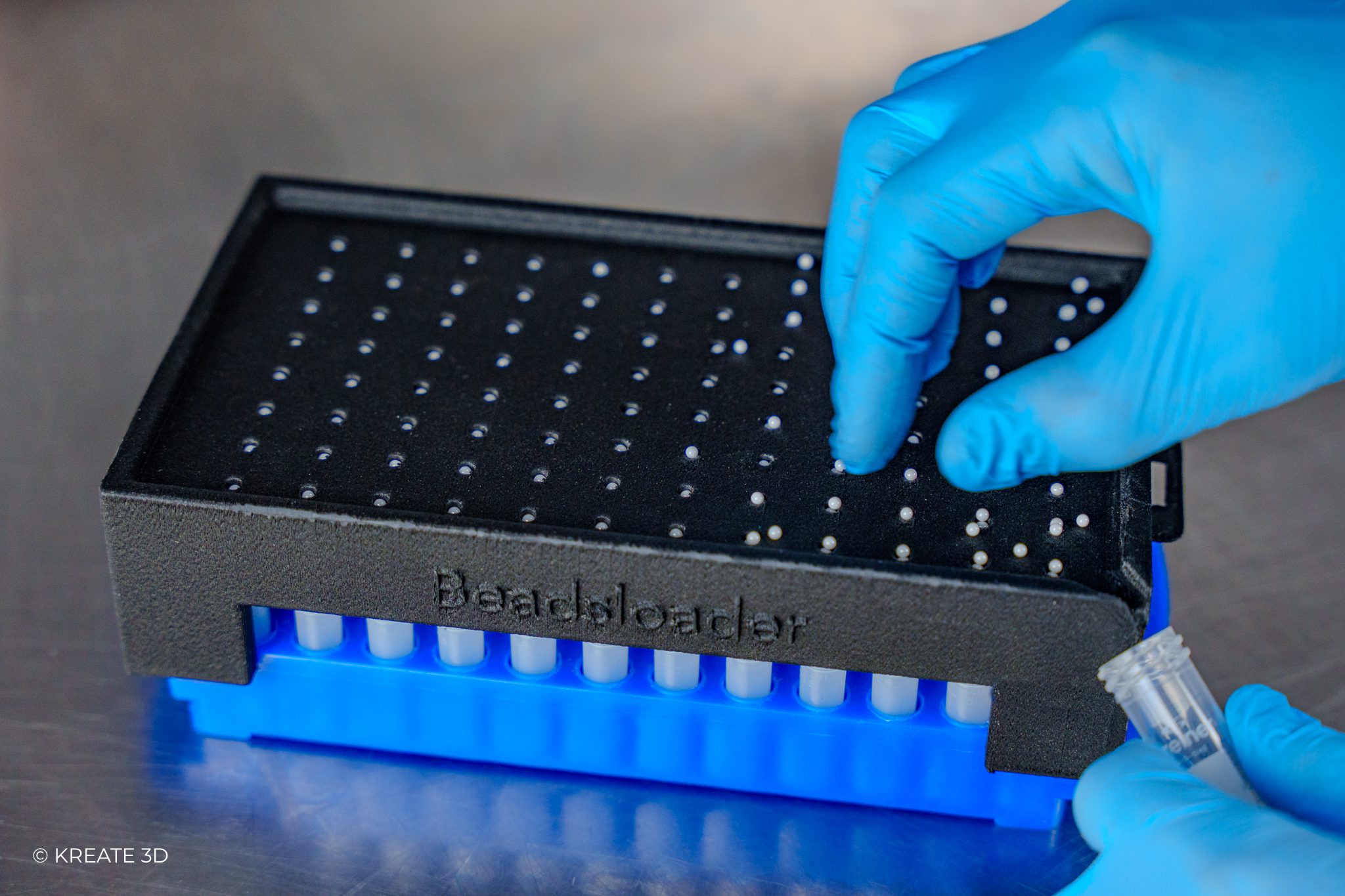

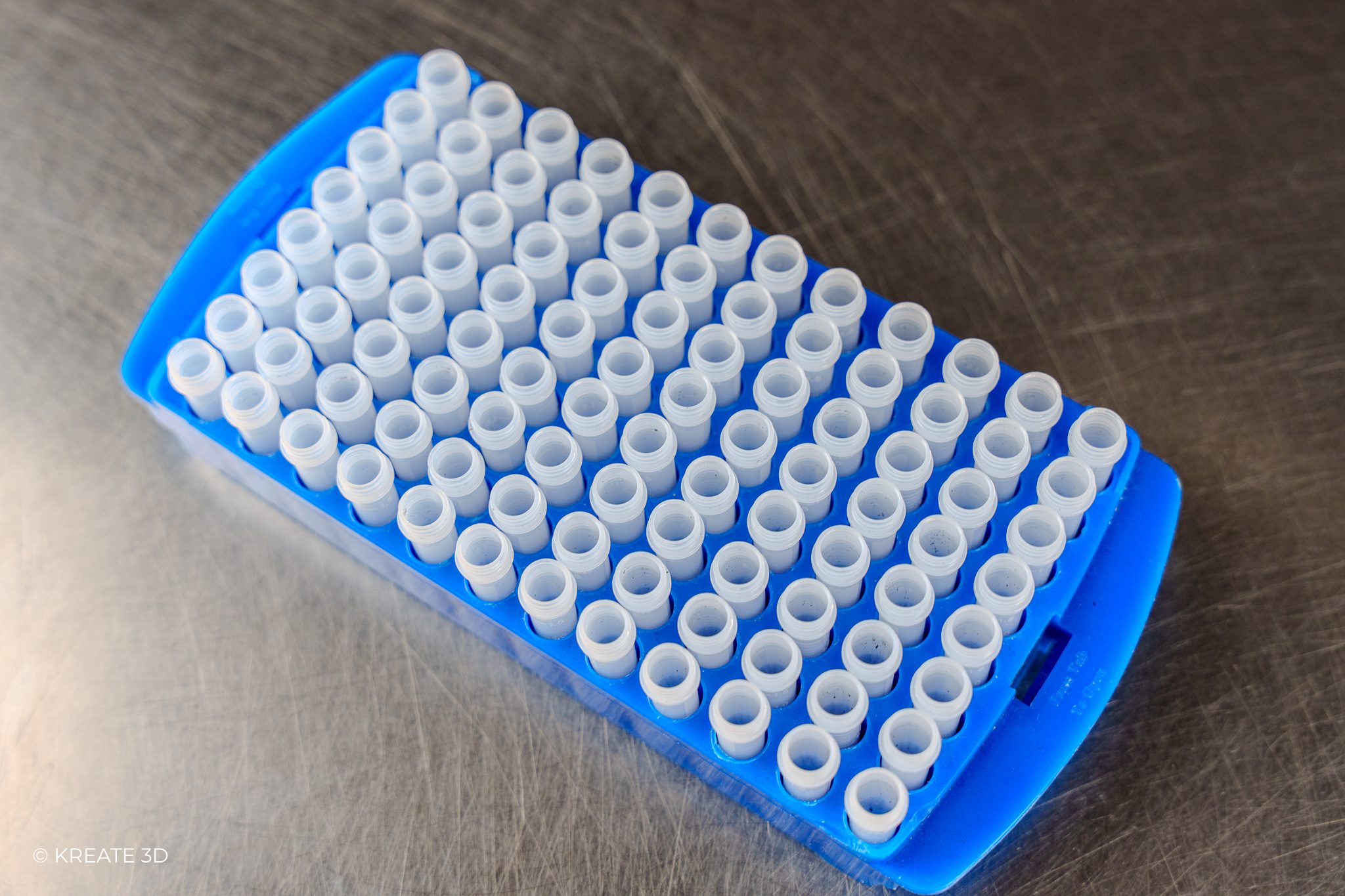

For the Rega Institute for Medical Research, Laboratory of Virology and Chemotherapy of the KU Leuven, we engineered and produced the Beadsloader (PATENT PENDING). This innovative tool revolutionizes the loading of small ceramic balls into test tubes, a task traditionally carried out painstakingly by hand with tweezers, leading to lengthy and frustrating processes.

Alternatively, with the implementation of the Beadsloader, laboratory workflows experience a seamless transition, resulting in heightened efficiency. Moreover, beyond its precision and efficiency, 3D printing offers cost-effective solutions for producing small-batch laboratory equipment.

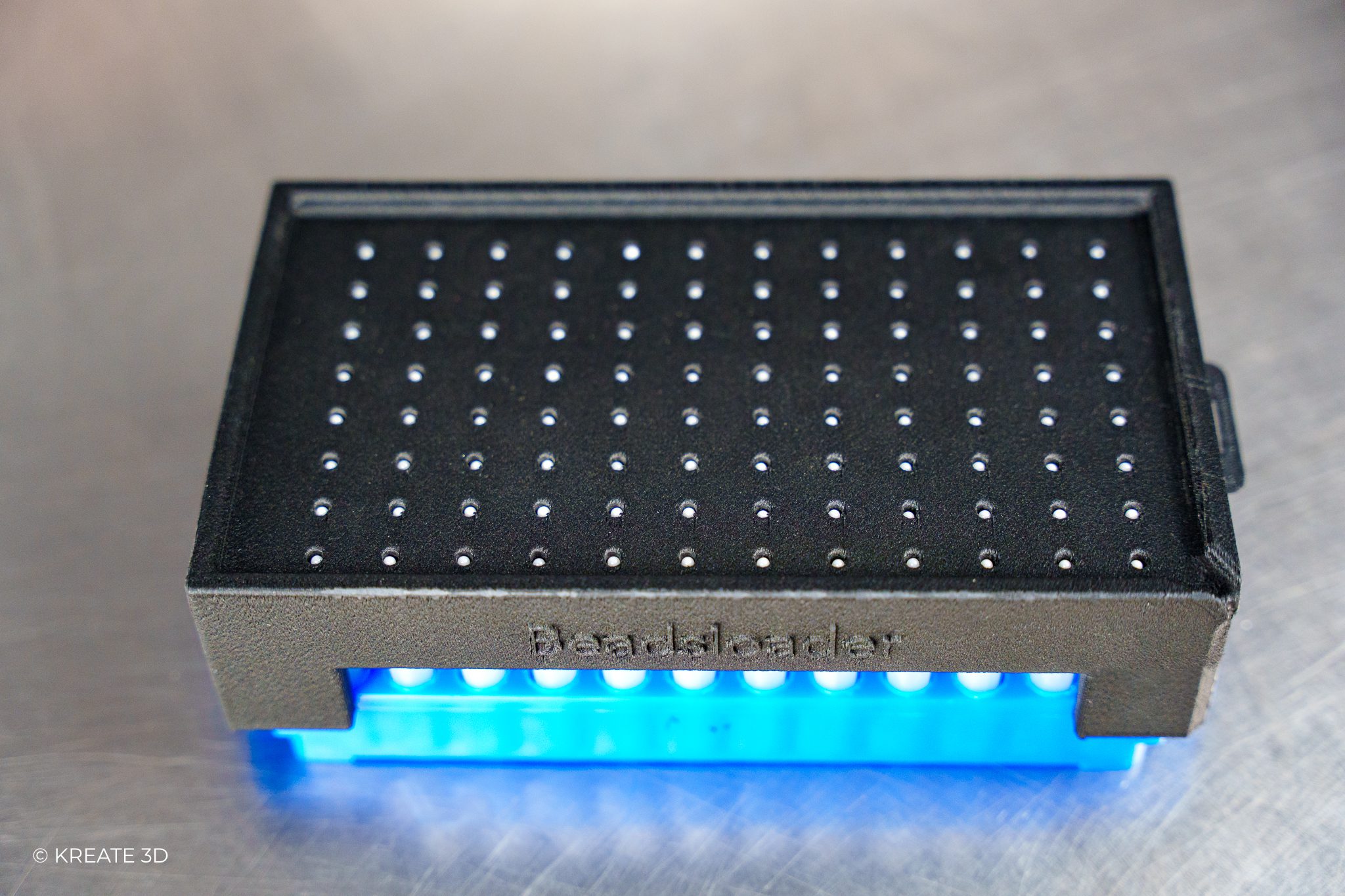

The 3D Printed Beadsloader

3D printing enables researchers to achieve precise geometries and intricate details previously unattainable. Furthermore, to ensure the correct functioning and precise dispensing of beads, a high degree of accuracy and specific material requirements were imperative.

Consequently, the beadsloader was meticulously designed and printed with an accuracy of 0.01 mm. Additionally, by utilizing PA12CF, a composite plastic consisting of Nylon infused with Carbon, ensured the fulfillment of these stringent demands. Firstly, this composite material boasts exceptional dimensional accuracy, crucial for sustained operational reliability.

Secondly, PA12CF also exhibits remarkable thermal and chemical resistance, facilitating sterilization through various methods including steam, chemical, and UV sterilization techniques.

Do you want to optimize your workflow? Interested in a beadsloader?

Feel free to reach out on [email protected] or use our contact form and schedule an appointment without any obligations!