3D PRINT MATERIALS & TECHNOLOGIES

WE OFFER A WIDE RANGE OF MATERIALS & TECHNOLOGIES

IN-HOUSE 3D PRINT TECHNOLOGIES

FDM TECHNOLOGY

(FUSED DEPOSITION MODELING)

I. Used for rapid prototyping / proof of concepts

II. Building low cost models

III. When precision and surface finish is less crucial

IV. When a specific thermoplastic is required

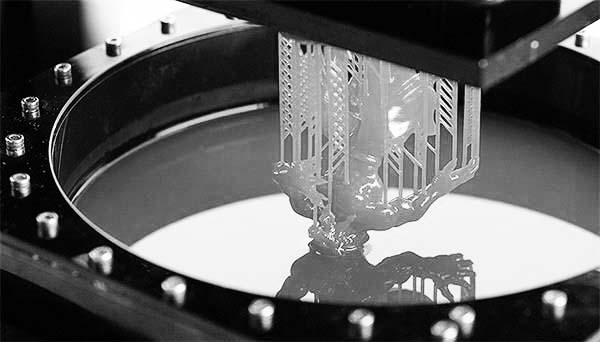

MSLA TECHNOLOGY

(MASK STEREOLITHOGRAPHY)

I. Functional and strong parts

II. Complex and highly detailed 3D prints

III. Faster printing time than FDM technology

IV. When serial or mass production is required

EVERY APPLICATION HAS ITS OWN MATERIAL REQUIREMENTS

Every project, design or 3D model is unique on its own and requires a different materiality. At Kreate 3D we offer a wide amount of materials for diverse applications.

FDM – PRINTING THERMOPLASTICS

PLA

Polylactic Acid

PLA is one of the most ecological and biodegradable materials available on the market. It is a rigid and strong material and quite flexible. PLA is used for conceptual and functional prints.

ABS

Acrylonitrile Butadiene Styrene

ABS is usually choosen over PLA when higher temperature resistance and higher toughness is required. This material is oil based and less environmentally friendly than PLA.

PETG

Polyethyleentereftalaatglycol

PETG is a very tough material with good thermal resistance. Its use is universal but especially suitable for mechanical parts and both indoor and outdoor use.

HIPS

High Impact Polystyrene

HIPS can withstand much higher impact forces than ABS. This material is easy to paint, machinable, can be sterilised with the H202 pressure method and is food-safe.

ASA

Acrylonitrile Styrene Acrylate

ASA has many properties that make it good for engineering and outdoor purposes. ASA parts are very heat-resistant, durable, rigid and strong.

TPU / TPE

Thermoplastic Polyurethane

TPU is mostly used for flexible applications, but its very high impact resistance can open for other applications.

PC

Poly Carbonate

PC is the strongest material of all, and can be an interesting alternative to ABS as the properties are quite similar.

CARBON

Carbon fiber filament

Carbon fibers are extremely strong and cause the filament to increase in strength, stiffness, much lighter and dimensionally stable.

MSLA – PRINTING PHOTOPOLYMERS

I. STANDARD

Standard 3D prints

The standard photopolymer resin is suitable for rapid prototyping and conceptual models.

II. ENGINEERING

Functional & strong prints

Looking for functional prints that can withstand forces? Our engineering resin will do the job.

III. FLEXIBLE

Flexible 3D prints

High detailed and flexible prints are possible with the Flexible Photopolymer Resin.

IV. ECORESIN

Ecological resin

If you are looking for an ecological solution, our machines are able to print with ecological resin.

ALMOST EVERY COLOR IS POSSIBLE.