SUPPLY CHAINS

We don’t need a global pandemic to rethink supply chains

We are currently more than a year into the global COVID-19 pandemic, and a lot has changed in our daily lives. We (mostly) work from home, kids are familiar with zoom-classes, take out diner became a regularity, and no one likes the word ‘bubbles’ anymore. One thing that has not been transformed at the same pace though, is our global supply chain system. Much of it is still in place, although the general sentiment around this system has changed, and has been changing ever since.

In the beginning of ‘the global lockdown’, a lot of analysts and experts warned us. The COVID-19 crisis was an awakening to the flaws in the global supply chain system, set up to flow more and cheaper goods to the masses, all in the pursuit of globalizing our Western consumption culture.

Although there was a period of uncertainty in the beginning, with a world waking up to a new-found crisis, after a while the global dance found its rhythm back. Ordering clothes or furniture was not met with the usual delays anymore. Once again, PPE was flowing from China to our borders and store shelves were plentiful of toilet paper. For a while, we didn’t take ‘choosing a brand’ for a viable option anymore, but with a couple weeks’ patience, lo and behold: there they were in all their consumerism glory.

What was recently more surprising regarding the fragility and weaknesses of our global supply chain system, is that we did not need a global pandemic to put it to a halt. All it took was one ship.

As everyone knows by now, the Suez Canal was blocked by one of the largest container ships in the world, named Ever Given. For nearly a week, this one ship blocked the entire canal and was holding up 10 billion dollars a day. The reason? “A gust of wind”, said the MV Ever Given’s owners. A trajectory analysis of the boat certainly leads to this conclusion, prior to more exhaustive research.

But think about this for a little while. 10 billion dollars’ worth of trade held up per day, by one ship, all because of a gust of wind. Given the lackluster reason (for now), frankly it is a miracle this hasn’t happened before.

Not the COVID-19 pandemic, but the events of previous weeks have truly highlighted the weaknesses in our global supply chain system, and the urgent need to rethink it.

One direct way to kick-start this effort, is to simply boost production at home in the traditional, familiar way. We know how to do this, so this seems like an easy way to get started. There is a plethora of aspects to consider in this reshuffle of our global supply system however. Applying the familiar method does not satisfy all of them. Higher wages and local tax rates, for instance, lead to a higher cost of goods, one of the main reasons companies started offshoring more and more in the first place, creating the fragile system we are living with in the process. There is a need to fundamentally change the way we look at producing goods.

At Kreate 3D, we have found a way to spearhead this challenge and offer a new direction forward, by changing the way we think about product development and using 3D printing as an accelerant. We keep each stage of the project in-house, from ideation to production, and as close to you – our client – as possible to assure you of a smooth collaboration.

In this way, we can achieve the closest realization of your original idea or pitch as possible.

Next to an experience that is smoother with more accurate results, we offer you one that is faster, cost-efficient and sustainable, by focusing on 3D printing with bioplastics in as much projects as we structurally can.

The technology is still not lightning fast, but in combination with a structured approach and in-house expertise, we can supercharge your project and let it evolve into a deliverable that is unique, perfectly suited to your specific needs, sustainable and cost-efficient.

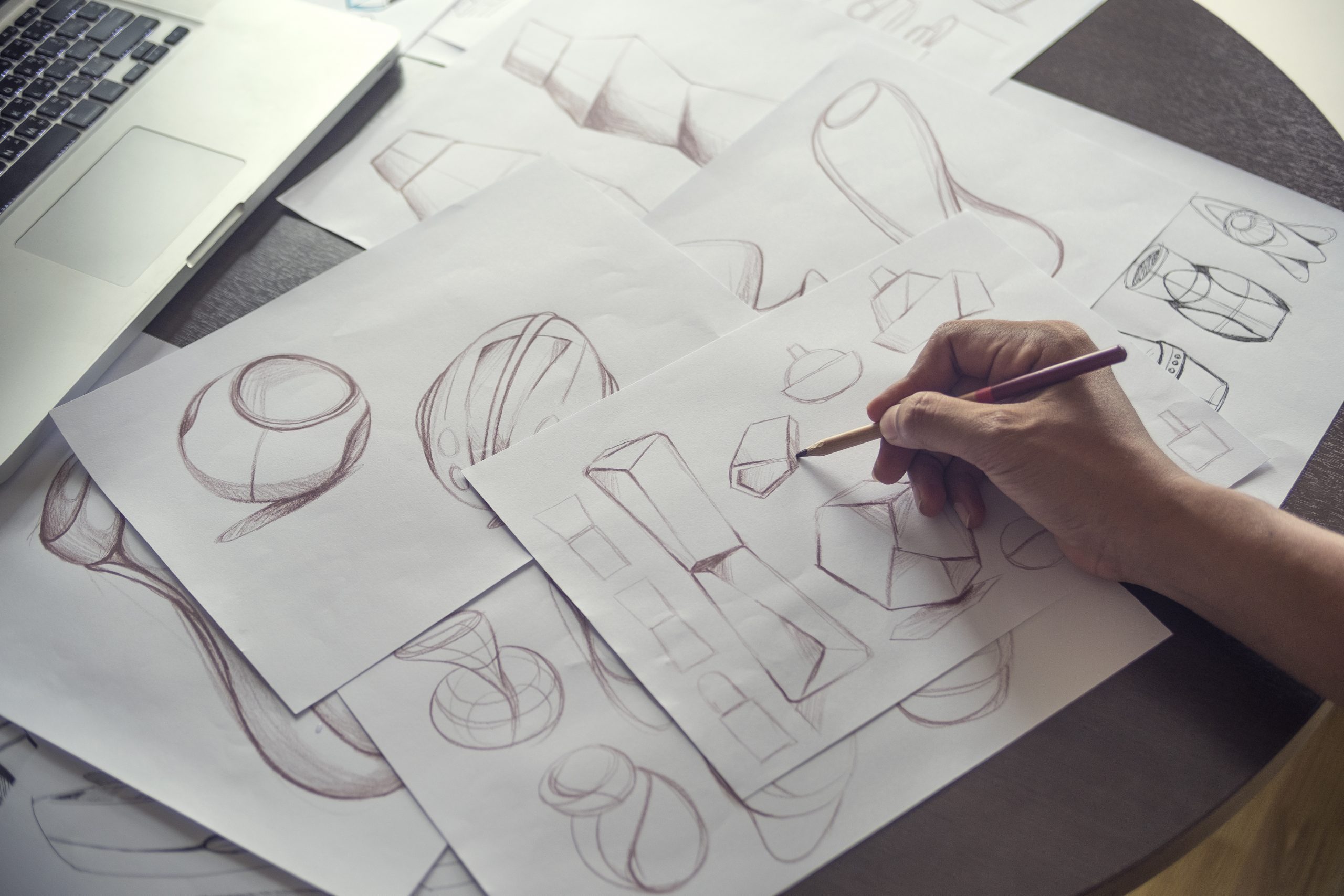

The ideation phase

The ideation phase is where we take your pitch, idea or concept, and transform it in about a week or two into a full-blown 3D model that is perfectly suited to your original intention. We also put it through a feasibility study, to determine which kind of materials are available to use. Each material has different structural properties and micro-deviations. We use sustainable materials when the project allows this, but only if this does not negatively affect your experience of the end-product.

Rapid prototyping

When this stage of the project is completed, the project goes through rapid prototyping. This process enables us to conceptualize more complex geometry, quicker. It keeps more options open, as we can explore and test real-life product materializations. We also avoid a large amount of production waste by precision printing each prototype.

Production

The final stage of the project is production. Here we can offer serial production to meet your desired project deadline. We still follow up each project, and all the in-house expertise we offer is not lost in translation. When your product is ready, we go over each nook and cranny in order to make sure everything is okay and up to your and our standards.

Are you ready to rethink how product development is done, from top to bottom? Learn more about Kreate 3D’s process and possibilities here.